|

In an earlier blog post I described how a solar panel can be used to heat water using the sun's radiant energy (not the electricity generated by the solar panel). This year we put the concept of heating water by collecting the sun's radiant energy coming through the back of the solar panel to work during our 35 day cruise. I mounted a custom made heat exchanger to the back of our 150 watt solar panel, added some insulation and a new back panel. Water is circulated from the boat water heater through the heat exchanger and back into the water heater using a small circulation pump that draws less than .4 amp.

Here is what we found during our 35 day cruise in northern Lake Huron: 1. Running the circulation pump for several hours midday on sunny days provided us warm water for showers and dish washing within two hours. 2. Water was heated from 60 degrees F to about 110 degrees F on sunny days. 3. Water was heated faster and to a higher temperature on calm days than on windy days. This is because the wind tends to cool off the front face of the solar panel. 4. We enjoyed warm water from the solar panel water heating system 12 days at anchor. Other days we either had warm water from running the engine to move the boat or the days were cloudy so no heat was collected. 5. The small circulation pump did not draw a significant amount of solar power. Besides, our batteries were topped off by early afternoon so we had plenty of excess power. 6. Having the system tapped into our boat's water system made it very convenient to take advantage of the warm water. 7. The added weight (10 pounds) of the water heating system was no problem for the pole brackets or stern rail. 8. I added a T and a valve in the solar heater tubing to make warm water available in the cockpit for showering or rinsing off after a swim. It worked perfectly. All in all, the system worked as planned and provided us with warm water conveniently when we needed it. Our next step will be to make a kit available to our customers to retro fit their solar panel systems or to order a water heating system with new installations. We will have kits available for both our larger 150-160 watt panels and our smaller 100-105 panels.

2 Comments

We tested our new 150 watt polycrystalline solar panel on a 35 day cruise in the North Channel area of Northern Lake Huron. This panel was equipped with the prototype of our solar water heating system which will be addressed in another blog entry. The solar panel was mounted on our pole mounting system and was rotated toward the sun The boat equipment and cruising pattern was essentially the same as last year (See prior blog entries). We were powering a freezer/refrigeration system, instruments, laptop computer, radios, autopilot, windlass and LED lights. Data was gathered using the remote display on our EP 10 amp dual output solar controller. The solar panel performance met our expectations. Our house battery bank consists of three 120 amp hour flooded batteries.

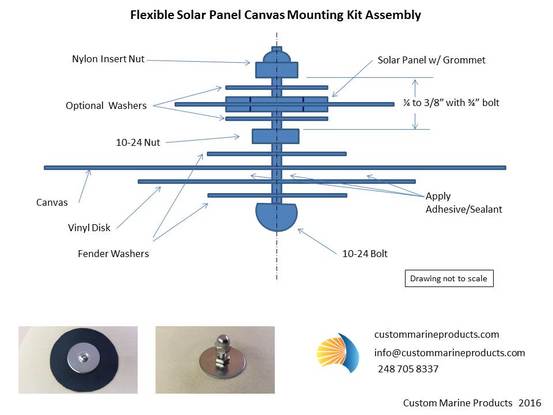

Both battery banks were usually fully charged by 2 PM when at anchor and on mostly sunny days so we often had excess power. Data comparing the performance of the 150 watt solar panel with our 140 and 160 watt panels is presented below. Average amp hours per day produced under various conditions: 150 Watt poly 140 Watt, poly 160 Watt, mono 160 Watt, mono 2015 2012 2013 2014 Overall average output per day 49 amp hours 53 amp hours 48 amp hours 48 amp hours Sunny days 60 69 71 69 Mostly sunny days 56 50 50 56 Mostly cloudy days 36 35 37 39 Cloudy days 22 32 28 20 Avg. Output on days at anchor 60 62 61 51 Avg. Output when engine was used 42 43 44 45 Min amp hrs for a day 4 27 28 4 Max amp hrs for a day 84 74 77 76 Max amps output 11.8 amps 10.5 amps 11.5 amps 11.4 amps This data is intended to provide a general idea of what to expect from the solar panels under various conditions. The two primary variables are the amount of sunshine and the running of the engine (the alternator charges the batteries so the controller shuts off power from the panels). Because the panel was equipped with a water heat collector on the back, it may have run hotter on sunny days when the water circulation pump wasn't run thus degrading the performance by up to 10%.The average panel output on sunny days at anchor with no motoring was 67 amp hours.  Two 50 Watt Semi-flexible Solar Panels Attached with Bolts, Nuts and Fender Washers. Two 50 Watt Semi-flexible Solar Panels Attached with Bolts, Nuts and Fender Washers. Several of our customers have recently attached their semi-flexible solar panels using nuts and bolts. Here is what they did: 1. Place the solar panel on the canvas and mark the grommet holes on the canvas. 2. Glue a vinyl disk about 2 inches in diameter to the underside of the canvas at points where attaching bolts will be placed. 3. Puncture a hole in the fabric through the vinyl. 4. Place a 1 inch diameter or greater plastic or stainless fender washer on a 10-24 or similar stainless bolt and pass it through the canvas. 5. Place another fender washer on the bolt on top of the canvas and secure with a nut. At this point, you have a reinforced canvas sandwiched between two fender washers. 6. Pass the bolt through the solar panel grommet and secure with an acorn nut. 7. Repeat for each solar panel grommet. See diagram below for details. On the installation shown above, the solar wires were run through the channel used to attach the canvas to the frame thus hiding most of the wiring. |

Categories

All

AuthorThomas Trimmer has been cruising with his Ericson 38 sailboat on the Great Lakes for over 20 years. He has pioneered the use of solar energy for wilderness cruising. He is continually designing and building equipment to simplify and enhance the cruising experience. Archives

April 2024

|

Efficiently Powering Your Vessel/Van. Call/email/chat any time, we're happy to help you work through designing your solar system.

Home Page Solar Panels Mounting Kits Product Page Marine Solar Systems Gallery of Installations Customer Comments Contact Us

Call 248 705-8337 or email [email protected]

Article On How To Size Your Solar Panels For Your Boat

Customer Reviews Return Policy Privacy Policy Shipping Times/Rates

Home Page Solar Panels Mounting Kits Product Page Marine Solar Systems Gallery of Installations Customer Comments Contact Us

Call 248 705-8337 or email [email protected]

Article On How To Size Your Solar Panels For Your Boat

Customer Reviews Return Policy Privacy Policy Shipping Times/Rates

RSS Feed

RSS Feed